Risk-based Maintenance

What is Risk-based Maintenance?

Maintaining Technical Objects, rather than simply waiting for them to break down, results in significant cost savings. The cost of repairing failed Technical Objects is three to five times higher than the cost of the same repair done in a planned manner before the failure occurs. Maintenance budgets are limited, so maintenance managers need tools to determine which strategy to pursue.

Risk-based maintenance management prioritizes the maintenance of technical objects that, if they were to fail, would pose the greatest risk to business continuity. This approach allows maintenance managers to determine how to use limited maintenance resources most economically to minimize the overall risk of failure of a technical object.

Assessing criticality

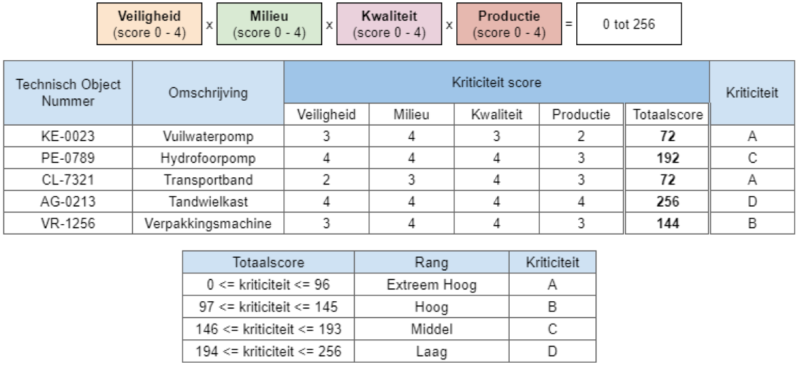

By understanding which assets are most important through an assessment of criticality, maintenance managers can determine how to most effectively schedule maintenance activities of technical objects. The criticality of technical objects is based on the consequences that occur in the event of a failure. Higher consequences lead to higher criticality. These can be consequences for safety, environment, quality or production. Below is a way to determine the criticality.

After assessing criticality, a risk-based maintenance program can be established based on the criticality ranking (A through D) of the technical objects.